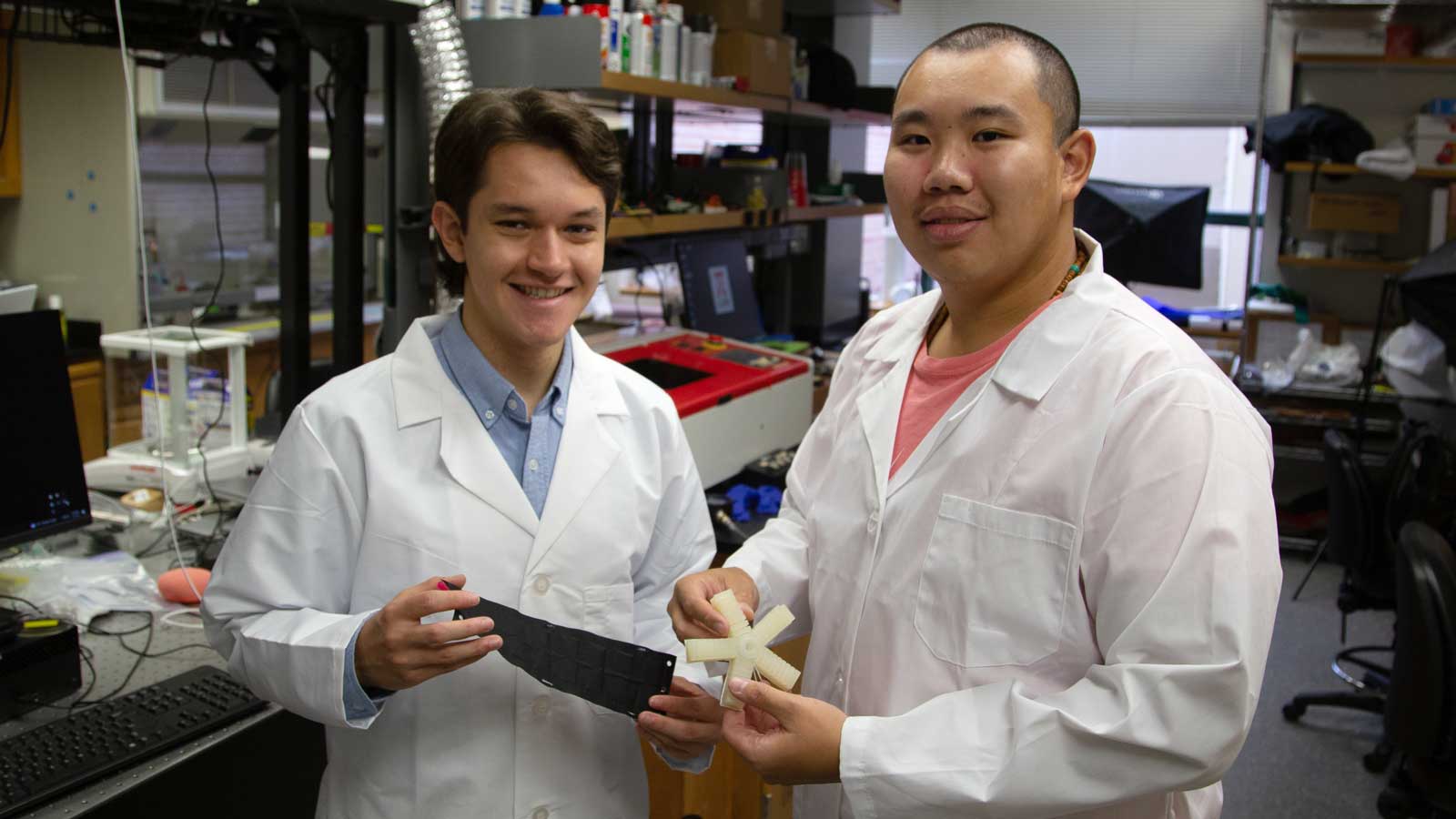

A paper authored by two Rice undergraduates in mechanical engineering (MECH) has been published in the peer-reviewed journal Frontiers in Robotics and AI.

Mark Schara and Mingde “Bryan” Zeng, both seniors, have worked in the Preston Innovation Lab of Daniel Preston, assistant professor of MECH, since they were freshmen. Their paper is titled “A Low-Cost Wearable Device for Portable Sequential Compression Therapy.”

The approach, known to clinicians as sequential compression therapy (SCT), is used to prevent cardiovascular disease and major cardiovascular events by intermittently compressing a patient’s legs to avoid overworking the heart as it pumps blood through the body. The current process is expensive and unwieldy.

The newly presented device is designed around a soft robotic actuator, known as a pouch motor, so it can be fabricated simply and at low cost. The researchers also made the fabrication process open access as an effort to make SCT more accessible.

“Imagine a series of inflatable pouches connected together. When deflated, they rest at their natural flattened length. When inflated, they expand and their length decreases since the perimeter of each pouch does not change, which occurs because the material is inelastic,” Zeng said. “Connect the head to the tail of the series of pouches and we have a ring that decreases in diameter when inflated.”

“Soft robotics is exactly what it sounds like,” Schara said. “Using soft materials to build the body, actuators and even the logic systems of robots, or in this case a medical device. Our device is fabricated from layered textiles and can be worn comfortably and treated as if it were any other piece of clothing.”

“Cardiovascular disease in the U.S. has an inverse relationship with socioeconomic status,” Schara said. “That’s why it’s important for our device to demonstrate that by adopting concepts from soft robotics, treatment for cardiovascular disease can become affordable for those who need it most.”

A week before their first class as freshmen, Schara and Zeng met through their membership in the Rice University Big Band.

“We discovered that we shared not only musical tastes but academic and career interests,” Zeng said. “We were both interested in making something meaningful during our undergrad years. That’s when we communicated with Dr. Preston. We spent half a year researching this topic and the next two years prototyping, testing, modeling and finalizing our device.”

When the COVID-19 pandemic started in 2020, much of their work was conducted remotely. Schara and Zeng worked around a 12-hour time difference and devised more than 20 prototypes.

“The final moment when all those efforts came together was unspeakably sweet,” Zeng said.

“Dr. Preston pushes the lab to produce high-quality work with candid, useful feedback,” Schara said. “He reserves plenty of time for undergraduates, even freshmen, and is willing to help us through difficult concepts.”